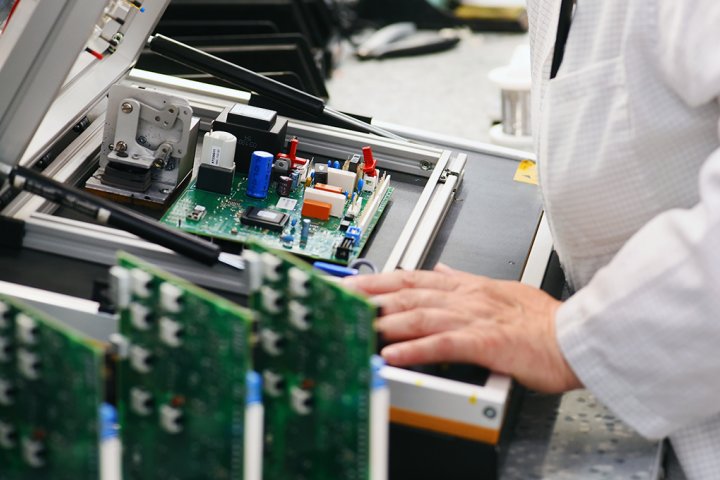

NPI & Prototyping

Communication is a crucial prerequisite for success when introducing a new product. At Semecs, you therefore have a single, clear point of contact.

It is responsible for ensuring that the process runs smoothly and that we can perform optimally in accordance with our agreements. We store all of the data in Microsoft Dynamics, our ERP system which we use to carefully control and monitor the project.